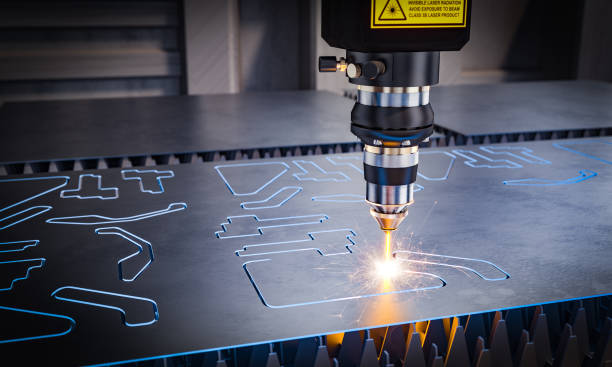

CNC Machining – Laser Cutting

Lasers are a productive and compelling apparatus for cutting metal and are broadly utilized in the metal creation and assembling enterprises. They are best, nonetheless, when joined with CNC machining.

Laser cutting works by centering a powerful laser onto the outer layer of the metal, normally engaged through an optical framework. The material is then taken out by being scorched, disintegrated, or blown away as a stream of gas, leaving an exactly cut edge and a top notch surface completion. Modern lasers are utilized to cut lines and cylinders as well as level sheet material.

How Lasers Work

A laser shaft is produced by invigorating a lasing material with electrical releases held inside a shut compartment. This creates a light emission that is then reflected inside the machine by utilizing a fractional mirror until it accomplishes sufficient energy to escape as a light emission shaded sound light. This light emission is then coordinated through fiber optics or potentially reflects and zeroed in on the metal to be cut. The cutting segment of the bar is extremely fine, generally less them 0.32mm in width.

Benefits Of Using CNC Machining Lasers

The benefits of utilizing lasers to cut metal rather mechanical cutting cycles include:

– It is simpler to keep the work-piece set up – mechanical cutting applies different powers that mean the piece must be positively cinched to keep it consistent.

– Decreased defilement – as there is no swarf, cooling liquid or outside sharp edge that can wear and leave stores, it is a much cleaner process.

– Better accuracy – actual edges wear and this can influence the line of their cut. Lasers are no impacted thusly and the cutting point doesn’t change.

– Decreased possibility of distorting – as there is no drag of an edge through the material, and the hot cutting point is extremely restricted, twisting from mechanical powers is stayed away from.